Mobile RO membrane cleaning service

RO membranes are the most important parts in pure water filtration systems, drinking water filtration systems, production water filtration systems, etc. Therefore, they need special care and monitoring for quality. Best water output at highest flow rate.

RO membranes operated for a certain period of time will lose performance and need to be considered for replacement. Because the cost of replacing a new RO membrane is very high, you need to find ways to extend the life of the membrane and maintain the membrane’s technical properties for as long as possible.

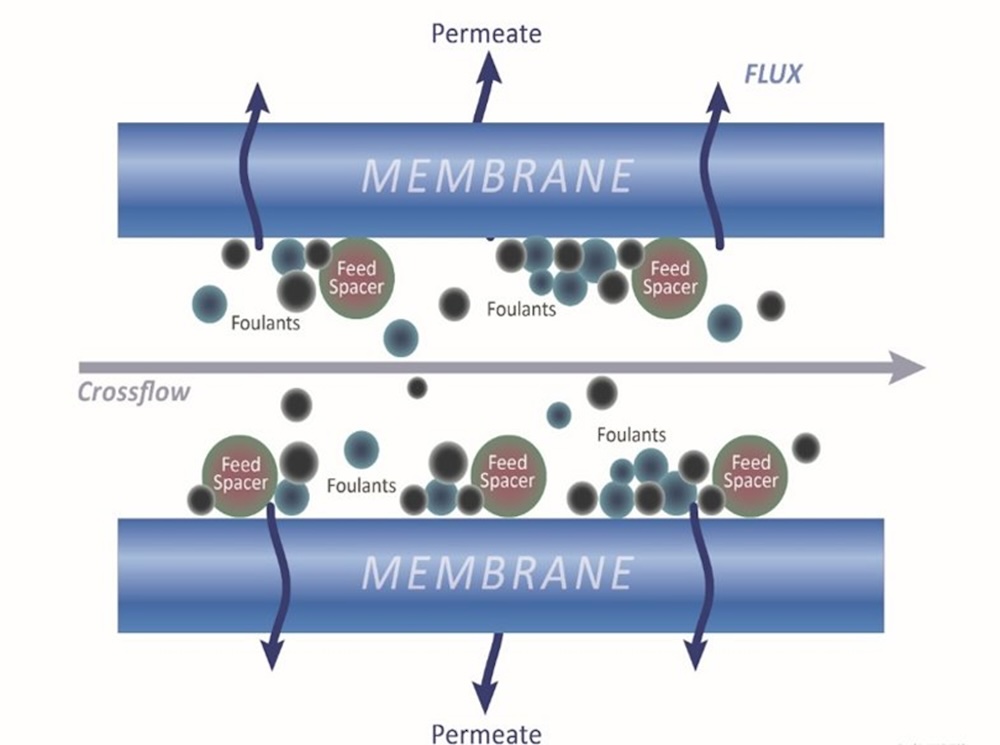

The CIP (Clean-in-place) method of washing RO membranes is the most popular method today to help clean dirt from the membrane that causes blockages and reduces membrane performance. After the CIP process, the RO membrane has the ability to restore almost its original working ability, at a rate of 70% – 98% depending on the level of fouling, fouling time, type of fouling substance and especially the CIP method as well as choosing the right CIP chemicals….)

When do I need to clean the RO membrane?

When you notice any ONE of the following changes:

- NPF (Normalized Permeate Flowrate) = Permeate flow rate reduced by 10 – 15%

- NDP (Normalized Differential Pressure) = Differential pressure from 10 – 15%

- NSP (Normalized Salt Passage) = The amount of salt passing through the membrane increases from 10 – 15%

The benefits of the above indicators bring:

- If these limits are exceeded for a long time, it may not be possible to recover as before!

- Helps you plan your membrane cleaning activities proactively

- Determine your plant’s standard membrane washing frequency and stick to it

What does the mobile RO membrane cleaning service include?

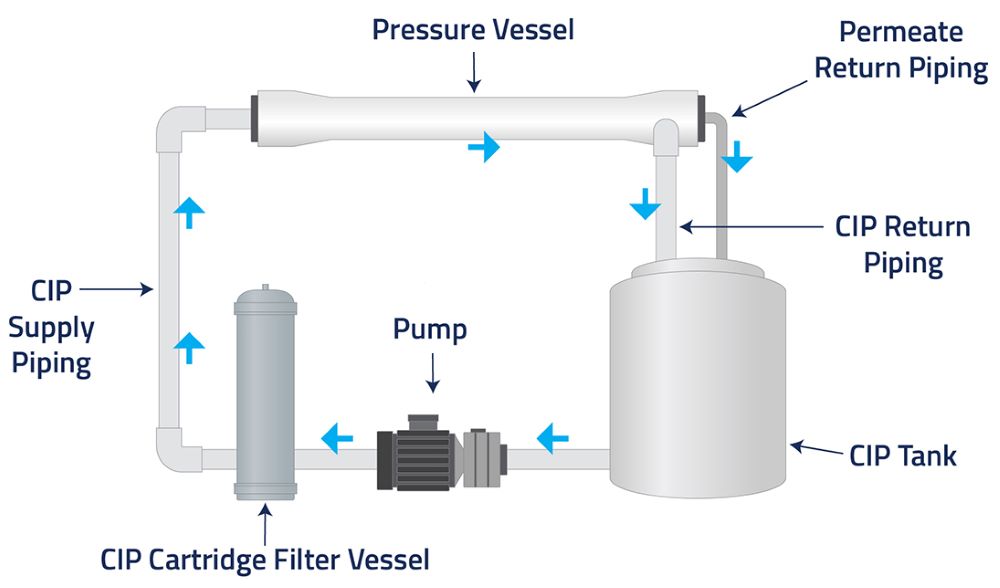

- We provide RO membrane cleaning service at your factory with our mobile CIP equipment installed on a complete skid that is easy to transport to your factory, CIP can be applied to the entire membrane. RO 4inch and 8inch. This mobile CIP unit will connect to your RO system or wash membranes on-site with our mobile skid.

- In addition, Song Phung Company also has the service of removing your RO membrane, bringing it back to the factory to conduct CIP at our factory and then delivering it back to you with an evaluation report on the effectiveness before and after CIP

Step-by-step CIP instructions for customers who already have a CIP system

- Before CIP the RO membrane, you need to run the RO system normally, then record the parameters (TDS, finished product flow, operating pressure, Delta P differential pressure, recovery rate…) here is Main parameters to evaluate the recovery ability of RO membranes after chemical CIP.

- Stop system operation. Turn off water in/out. Connect the system to the CIP system or remove the RO membrane and install it via a portable CIP skid.

- Supply clean water into the CIP tank, up to about 70-75% of the tank capacity, and pre-rinse with clean water. Rinsing with clean water first confirms that the CIP flow path has been adjusted properly.

- Supply CIP chemicals into the CIP tank, the type of chemical will be determined according to the cause of scaling and fouling

- Check the pH in the CIP tank to ensure the pH of the acid cleaner is around 2 and the pH of the alkaline cleaner is around 12. Open all valves on the CIP system.

- Turn on the CIP pump to circulate.

- When the CIP pump is running, some water escapes through the permit product line, so the return pipe should be returned to the CIP tank.

- Check pH about every 10 minutes. Provide additional chemicals if pH changes.

- Run circulation at 30 – 60 and maintain pressure level below 4 bar. You can stop running for 15 – 30 minutes to soak.

- Continuously check the water level in the CIP tank, supply water and chemicals to ensure pH conditions.

- Isolate the CIP system from the system by closing the CIP valves. Discard all remaining water in the CIP system. Clean and preserve the CIP system for future cleanings.

- Reopen the valves on the system. Supply clean water into the system for washing and drain all washing water along the discharge line.

- After rinsing with clean water for about 30 minutes, turn on the system’s water supply pump to wash in operating mode, and drain all finished water.

- Adjust the RO system to normal operating state. Check finished water TDS, running pressure and finished water flow compared to initial results included in the report.

Steps to receive RO membrane CIP service

- Survey the existing RO filtration system

- Evaluate the scale and select the appropriate CIP plan

- Consulting service quotes

- Make a detailed plan

- Approve the plan

- Perform CIP services

- Make effective evaluation reports

- Service performed by Song Phung

Please contact SongPhung via hotline to receive more accurate advice and quotes for your RO system.