38650 vacuum breaker valve

Brand: iGlobal

Origin: China

$22,57

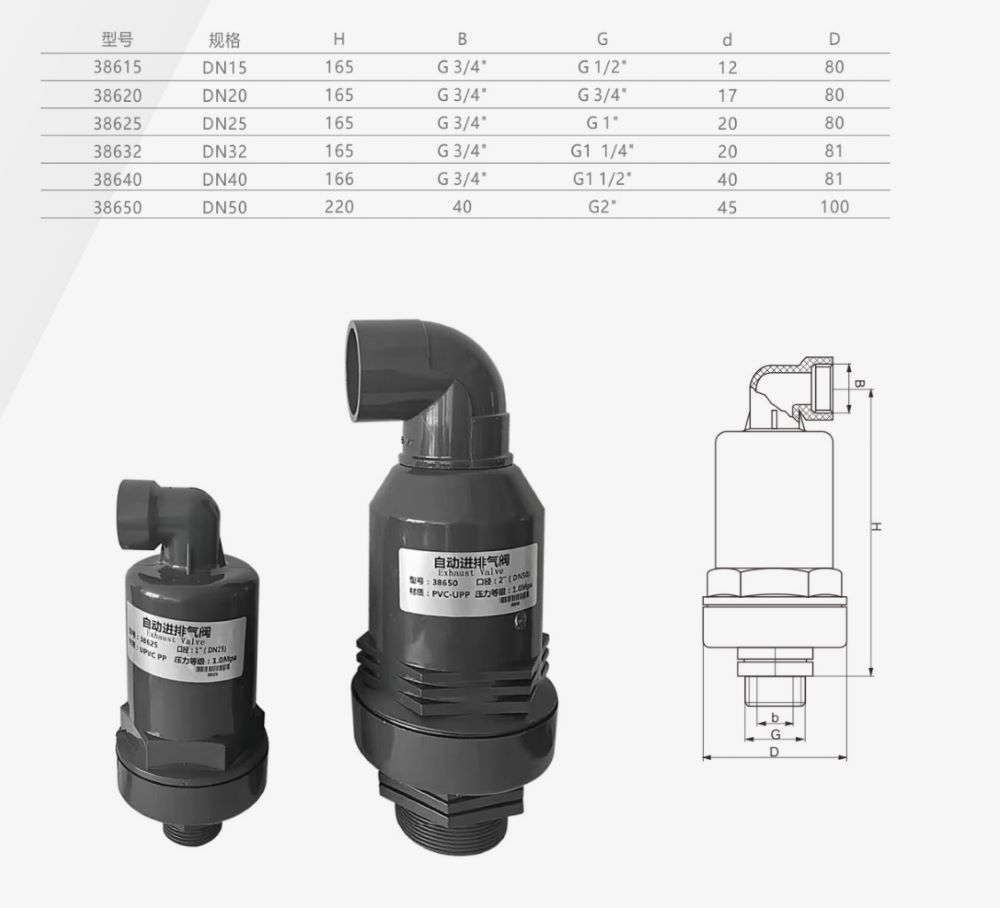

- Model: 38650

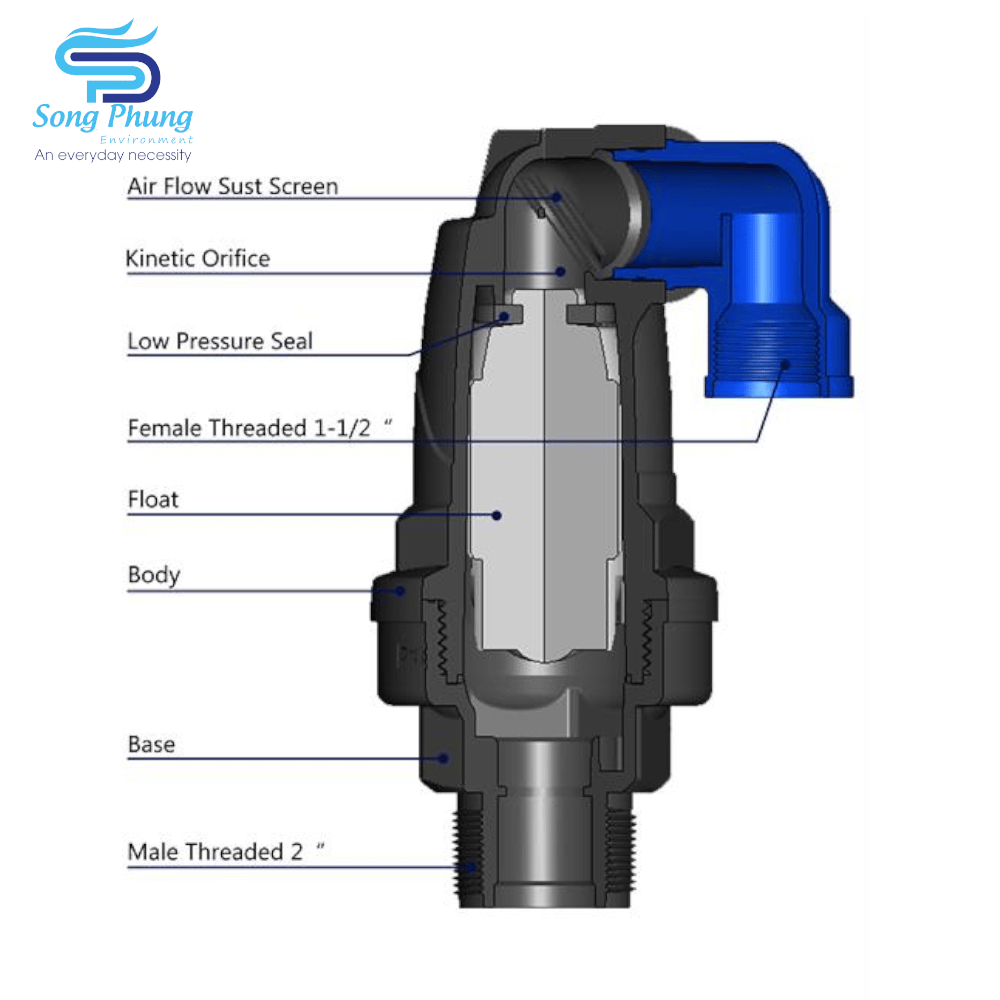

- Material: PP

- Dimension: D100mm, H220mm

- Connection: fi60, 2″M

- Air inlet: D40mm

- Max pressure: 1MPa

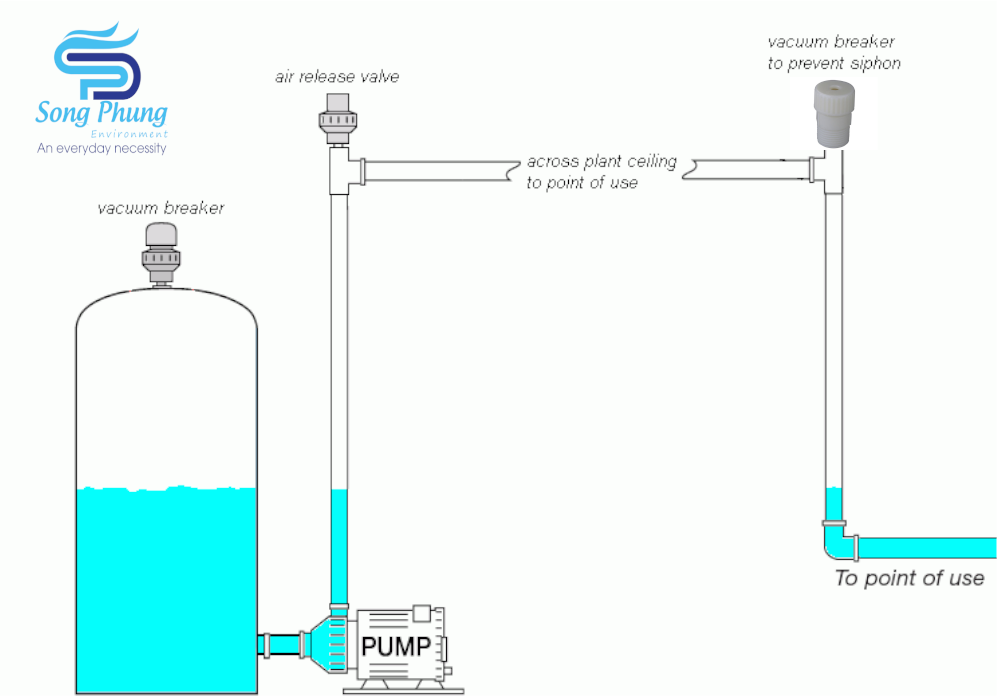

- Application: protect tanks, pipes and other equipment from the suction of negative pressure

- Origin: Chihon

PROMOTION

- Get an immediate 5% discount on your total order when purchasing more than 10 units of product. Please log in to cart and checkout to receive the offer immediately

- Pay with MoMo and get 2% discount - View your cart

SALES POLICY OF SONG PHUNG

- Product unit price: VAT included

- Commitment to quality: With every product sold, we are always committed to providing quality to customers. For any complaints, you can contact directly to hotline 0913 90 72 74

- Product: 100% genuine, original, original packaging

- Warranty: 12 months, return within 14 days if there is a manufacturer defect

- Transportation and installation: Reputable - fast - on time

- After-sales service: Peace of mind, dedicated to customers.

Reviews

There are no reviews yet.