Electromagnetic dosing pump 6.3LPH@3.5bar

Brand: Sandur

Origin: India

$187,53

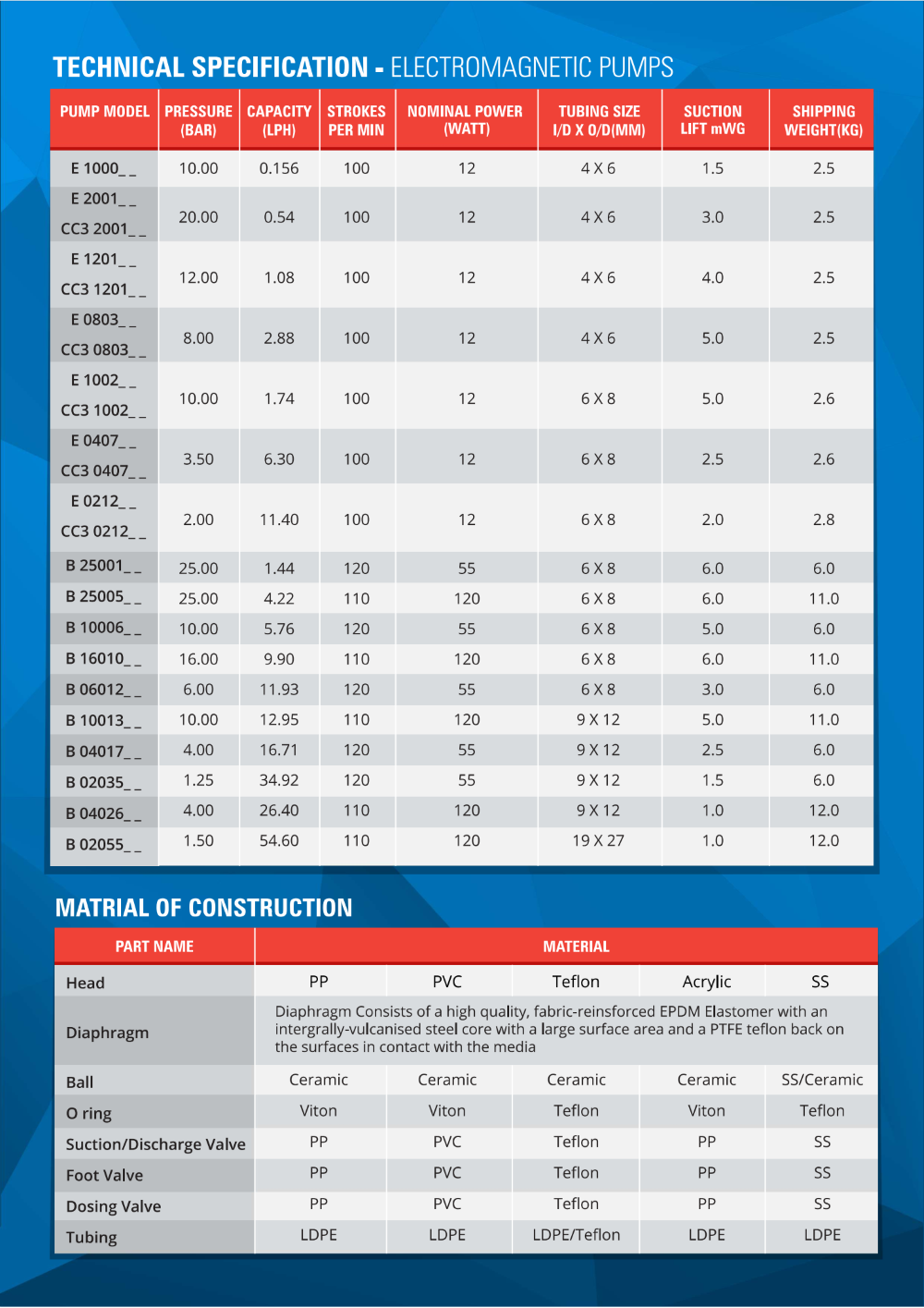

- Model: CC3 0407 PP

- Capacity: 6.3 L/H

- Pressure: 3.5 Bar

- Power: 12 W

- Suction lift: 2.5m

- Shipping weight: 2.6kg

- Pump head material: PP

- Diaphragm material: PTFE

- Ball material: Ceramic

- Tubing material: LDPE

- Application: Filling pipes, tanks, transporting chemicals from one place to another

- Supply includes: Foot valve, dosing valve, 2m suction/discharge

- Origin: Sandur

PROMOTION

- Get an immediate 5% discount on your total order when purchasing more than 10 units of product. Please log in to cart and checkout to receive the offer immediately

- Pay with MoMo and get 2% discount - View your cart

SALES POLICY OF SONG PHUNG

- Product unit price: VAT included

- Commitment to quality: With every product sold, we are always committed to providing quality to customers. For any complaints, you can contact directly to hotline 0913 90 72 74

- Product: 100% genuine, original, original packaging

- Warranty: 12 months, return within 14 days if there is a manufacturer defect

- Transportation and installation: Reputable - fast - on time

- After-sales service: Peace of mind, dedicated to customers.

Reviews

There are no reviews yet.