Pure water production line business can be considered a profitable profession. Therefore, many people want to invest in this field but still do not know how much it costs to prepare, which address provides quality water filtration equipment, etc. The following article will provide the necessary content aforesaid to the customer.

Price list of equipment for bottled purified water production line

Depending on the scale, the clean water production line will have equipment with different prices. A production line system for bottled purified water includes the following equipments:

| Name of products | Price (Unit: VNĐ) |

| FRP Filter tank (3sets: Iron removal + GAC + softener) | 500.000 – 80.000.000 |

| Filter pump | 3.000.000 – 20.000.000 |

| Cartridge filter | 2.000.000 – 30.000.000 |

| High pressure RO pump | 500.000 – 8.000.000 |

| ROMembrane | 500.000 – 14.000.000 |

| Ozonator machine | 1.000.000 – 50.000.000 |

| 0.2mcicron filter | 500.000 – 20.000.000 |

| UV system | 700.000 – 70.000.000 |

| Filling water pump | 2.000.000 – 20.000.000 |

| Conveyor | 3.000.000 – 20.000.000 |

Price list of equipment for pure water production line

In addition to purchasing equipment, the installation of a pure water production line also requires some costs such as:

- Rental cost: The area sufficient for the pure water production line to operate is from 60 to 100m2.

- Fees for business registration procedures.

- Expenses for drilling wells, finding water sources for production.

- Cost of importing plastic bottles, labeling, packaging, etc.

- The cost of hiring.

- Costs for electrical panel systems, control equipment, electrical cabinets, etc.

What does the bottled water production business need?

In addition to estimating a capital, the business of bottled pure water production line also requires careful preparation in all aspects such as:

- Search and survey suitable factory opening address. Because this is a pure drinking water item, it requires high cleanliness. Therefore, the location chosen for the factory should be away from waste treatment areas, chemical plants, livestock farms, etc.

- Must have knowledge and experience in the field of bottled water production.

- Prepare infrastructure and power source, water source, waste discharge system suitable for equipment in pure water production line.

- Choose a reputable equipment supplier such as Song Phung Environmental Company.

- Depending on the size of the business, customers may need to consider investing in automatic or manual bottling lines.

- Contact suppliers of packaging, plastic bottles, printing stamps, labels, etc. for brands.

- Prepare vehicles to transport products to distribution.

- There should be a generator to ensure the pure water production line is continuous.

- Have a plan for training personnel and marketing for business activities.

It is best to reserve a sufficient amount of money to maintain the plant operation for 6 months in order to prevent the risk of accidents.

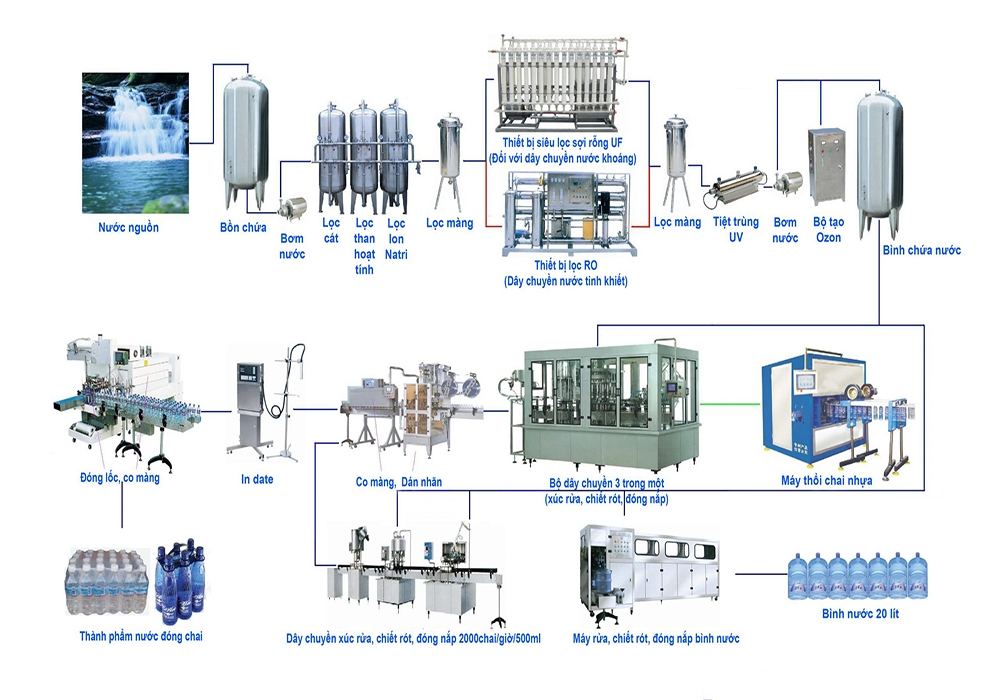

How does the pure water production process work?

With the modern filtration equipment provided at Song Phung Environmental Company, the bottled purified water production line of the customer is guaranteed to meet safety standards and bring a great feeling of refreshment to customers.

Stage 1: filtering alum water upstream – coarse filtration

The water source when pumped from the well is usually relatively clean, of stable quality, easy to handle, and contains many minerals. However, to put it into production, it must be tested very closely to ensure this is a safe source of water, free of bacteria or any heavy metals. This step of testing is intended to estimate the cost of water treatment.

After that, the water source will be put into the first step in the pure water production line:

- Deodorization and decolorization: Through the coarse filter system, dirt particles with a size of over 5 micrometers will be removed. Then some active ingredients will be added to the water to deodorize.

- Removal of heavy metals: The filter column in this stage contains highly oxidizing filter materials such as activated carbon, Manganese sand, etc.

- Water softening: This is the process of reducing metal ions such as Mg2+, Ca2+, Cl-, NO3-,…

Stage 2: reverse osmosis through RO membrane – fine filtration

After stage 1, water will be pumped high pressure to the RO membrane with a mesh filter with pore size as small as 0.001 micrometer. After this stage, the water will be removed up to 95% of bacteria and become completely pure. Parts of water containing impurities, dirt, metal ions, etc. will be processed into waste or recovered for rotation.

Stage 3: disinfection

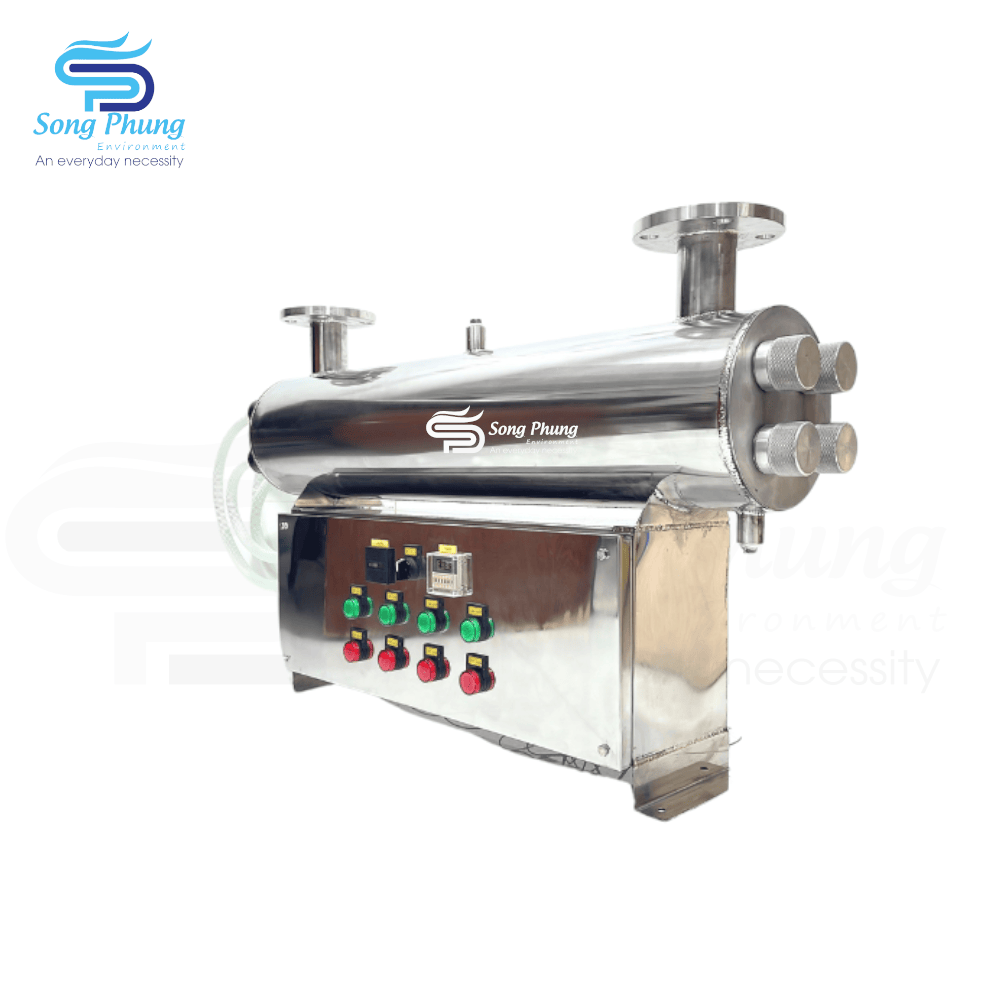

Theoretically, the water after passing through the RO membrane is drinkable. However, to ensure safety, the water will be disinfected with an Ozone machine and UV lamp before being extracted into the bottle.

- Ozone is a natural cleaning agent that helps kill bacteria, deodorize, etc., without changing the composition of the water. Ozone has a structure of O3 with an unstable structure and will quickly split into positively and negatively charged oxygen atoms. These atoms will compete and break the structure of the bacterial cell.

- UV lamp (also known as ultraviolet lamp) will generate electron currents with radiation level of 2,537Ă, capable of killing bacterial spores and cysts without changing water quality.

After being destroyed by Ozone machine and UV lamp, the dead bacteria will be completely removed through the ultrafiltration device.

Stage 4: extracting, pouring pure water into a 20 Liters bottles

This is the final stage in the purified water production line, including the following:

- Check, rinse the water tanks and immerse the lids in the sterilized solution.

- The automatic filling and filling system fills the containers with treated water and closes the lid.

- Label, print information and box finished products.

Finally, the sterilized, quality assurance 20 Liters water bottles will be transported to the distribution unit to serve consumers.

Address to supply and install pure water production line

Song Phung Environmental Company is a reputable address specializing in providing water purification equipment, replacement accessories and complete filtration systems.

A team of experienced professionals, high product quality and good prices are the outstanding advantages that the company brings to customers. In addition, Song Phung Environmental Company also provides consulting solutions for design, installation, operation, and technology transfer of pure water production lines.

Currently, the company has been honored to cooperate with more than 5000 customers and implement more than 4000 business projects.

Hopefully, through the information that the article provides, the customer has made appropriate calculations for the intended installation of a pure water production line. If you need more advice, please come to Song Phung Environmental Company (address in Ho Chi Minh City) or contact via website https://thietbinganhnuoc.com.

Learn more: Instructions for installing a filter distributor for composite filter tank

Contact hotline: 0913.90.72.74 to order in bulk, the most preferential price!

Follow Fanpage: https://www.facebook.com/SongPhungthietbinganhnuoc/ to update new products.

Translator: Duong Nguyen Hoang Khang